About Stainless Steel

Stainless steel is an alloy of iron that has had at least 10% chromium added to improve corrosion resistance. The designation 18-8 refers to stainless steel that has approximately 18% chromium and 8% nickel—it generally applies to types 301, 302, 303, and 304.

Most types of stainless steel harden while being worked and cannot be

hardened by heat treating. They usually are provided in an annealed (not

hardened) condition although some of these alloys, such as Type 301, may

be work-hardened to a greater hardness ( 1/2 hard, full hard, or spring

temper) for applications such as springs.

Other types of stainless steel, such as Type 410 and Type 440C, can be

heat treated to improve strength and toughness.

Usually these are provided in an annealed (not hardened) condition to

make them easier to work. They also may be heat treated after the final

product is formed to achieve better strength and toughness.

For applications requiring limited machining and cutting prior to use,

some alloys are provided already heat treated.

Unpolished (Mill) Finish— No finish is applied.

Alloy is sold as fabricated by the mill.

Unpolished (#2B Mill) Finish— Semi reflective finish

as fabricated by the mill.

Brushed (#3 Satin) Finish— Polished to a brushed

finish on one side so grain lines will be in one direction.

Brushed (#4 Satin) Finish— Polished to a fine brushed

finish on one side so grain lines will be in one direction.

Mirror-Like (#8) Finish— Polished to a mirror-like

finish on one side. It's free of grain lines.

Note: 420V, Nitronic 60, 15-5 PH, 17-4 PH, and A286 are not rated.

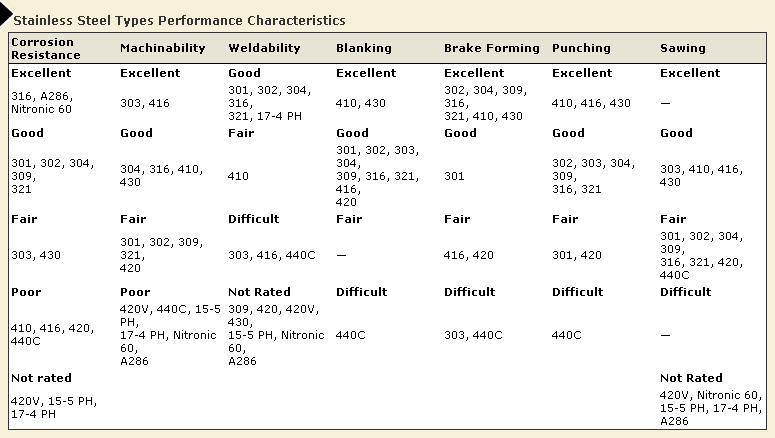

| Excellent | Good | Fair | Difficult | |

| Blanking | 410, 430 | 301, 302, 303, 304, 309, 316, 321, 416, 420 | --- | 440C |

| Brake Forming | 302, 304, 309, 316, 321, 410, 430 | 301 | 416, 420 | 303, 440C |

| Punching | 410, 416, 430 | 302, 303, 304, 309, 316, 321 | 301, 420 | 440C |

| Sawing | --- | 303, 410, 416, 430 | 301, 302, 304, 309 316, 321, 420, 440C | --- |

| Excellent | Good | Fair | Poor |

| 303, 416 | 304, 316, 410, 430 | 301, 302, 309, 321, 420 | 420V, 440C, 15-5 PH, 17-4 PH, Nitronic 60, A286 |

Note: 309, 420, 420V, 430, 15-5 PH, Nitronic 60, and A286 are not rated.

| Good | Fair | Difficult |

| 301, 302, 304, 316, 321, 17-4 PH | 410 | 303, 416, 440C |

Good— Resists outdoor, industrial, marine, and mild chemical environments.

Fair— Resists outdoor, industrial, and mild chemical environments.

Poor— Resists outdoor environments.

| Excellent | Good | Fair | Poor | Not Rated |

| 316, A286, Nitronic 60 | 301, 302, 304, 309, 321 | 303, 430 | 410, 416, 420, 440C | 420V, 15-5 PH, 17-4 PH |

Commonly used in gears, cams, and aircraft parts. Combines high strength and wear resistance. Can be heat treated at low temperatures to increase mechanical properties. Magnetic. Temperature range not rated.

Maintains high strength and wear resistance. Slightly higher chromium content for improved corrosion resistance over Type 15-5 PH. Can be strengthened by precipitation hardening at low temperatures. Magnetic. Temperature range not rated.

High strength. Good response to heat-treating. Moderate corrosion resistance.

Nitrogen provides better corrosion resistance than Type 304 plus more strength in temperature extremes. Commonly used in chemical industry. Nonmagnetic. Cannot be heat treated. Temperature range not rated.

Nitrogen provides better corrosion resistance and more strength in temperature extremes than Type 316. Used in chemical industry. Nonmagnetic. Temperature range not rated.

Most strain-hardenable chromium-nickel stainless steel. Better wear resistance, fatigue strength than Type 304. Retains strength while stretching like 1095 steel. Good weldability, temperature resistance. May be slightly magnetic. Cannot be heat treated. Maximum corrosion resistance temperature 1550° F; minimum not rated.

Higher carbon content for slightly higher strength than Type 304 with same corrosion resistance. Cannot be heat treated. Maximum corrosion resistance temperature 1600° F; minimum not rated.

Corrosion resistant. Meets Type 302 and Type 304 standards. Wire meets ASTM A580; spring wire meets ASTM A313 (choose extra-bright when a fine surface finish is important).

Sulfur and phosphorus increase machinability. Low-carbon chromium-nickel (austenitic). Good corrosion, temperature resistance. Only strain harden (cold form - may become slightly magnetic). Can't be heat treated. Maximum corrosion resistance temperature 1600° F; minimum not rated.

Most widely used stainless steel. Good weldability, formability, and temperature resistance. Only strain harden (cold form - may become slightly magnetic). Cannot be heat treated. Corrosion resistance temperature range -320° to 1600° F.

This dual certified 304/3004L stainless steel is a reduced carbon version of Type 304 stainless steel.

Similar composition to Type 304. Low carbon chromium-nickel (austenitic). Excellent temperature resistance. Good corrosion resistance. Only strain harden (cold form - may become slightly magnetic). Can't be heat treated. Maximum corrosion-resistance temperature 1795° F; minimum not rated.

Higher molybdenum content provides better corrosion resistance. Low carbon chromium-nickel (austenitic). Good weldability and temperature resistance. Only strain harden (cold form - may become slightly magnetic). Cannot be heat treated. Maximum corrosion resistance temperature 1600° F; minimum not rated.

This dual certified 316/316L stainless steel is a reduced carbon version of Type 316 stainless steel.

Low carbon chromium-nickel (austenitic). Titanium provides superior weldability. Only strain harden (cold form - may become slightly magnetic). Cannot be heat treated. Maximum corrosion resistance temperature 1600° F; minimum not rated.

Chromium alloy (martensitic). Can be heat treated for extra hardness and improved wear resistance. Not recommended for highly corrosive environments. Not recommended for welding. Maximum corrosion resistance temperature 1300° F; minimum not rated.

Sulfur provides better machinability than Type 410. Chromium alloy (martensitic). Can be heat treated. Magnetic. Maximum corrosion resistance temperature 1250° F; minimum not rated.

Excellent polishability. High hardness. Ideal for manufacturing plastic molds. Composition and properties fall between Type 410 and Type 440C. Can be heat treated. Magnetic. Maximum corrosion resistance temperature 1150° F; minimum not rated.

Shim stock material. High wear resistance. Rockwell hardness is C49-C53.

Base of Type 420C with added vanadium and carbon for improved wear resistance. Powder metal process improves corrosion resistance. Can be used in place of tool steels, such as D2, when extra corrosion resistance is important. Temperature range not rated.

Chromium-based (ferritic) alloy. Good formability. Magnetic. Cannot be heat treated (strain-hardening has little effect). Room temperature alloy. Not recommended for temperature extremes or outdoor use. Chosen more for aesthetic purposes.

Also known as razor blade stainless steel. Rockwell hardness C49-C53.

When heat treated, one of the hardest stainless steels. High carbon content provides good wear resistance. Magnetic. Ideal for bearings, valve parts, and knife blades. Temperature range not rated.